Application requirement:

Visual inspection of galvanized pipes to check welding defects inside the pipes in the range of 15 mm dia to 300 mm dia.

Jindal Industries requires visual inspection of MS Black and Galvanized Pipes to check welding defects inside the pipes to ensure pipe are free from welding defects.

Solution:

Jindal Industries uses RPIC2 pipe inspection camera for visual inspection of high-quality MS Black and galvanized Pipes in the range of 15 mm dia to 300 mm dia.

The goal being of feasible weld inspection to see visual welding defects inside the pipes in 10 to 20 meters length range. RPIC2 Pipe Inspection camera system is a ruggedized, professional video inspection camera equipped with a 7'' LCD monitor with DVR and 20m rotatable cable reel. At the time of pipe manufacturing, a welding process happens to join the sheet metal and complete a shape of the pipe. It is important to do quality checks through inspection & ensure pipe is free from all welding defects.

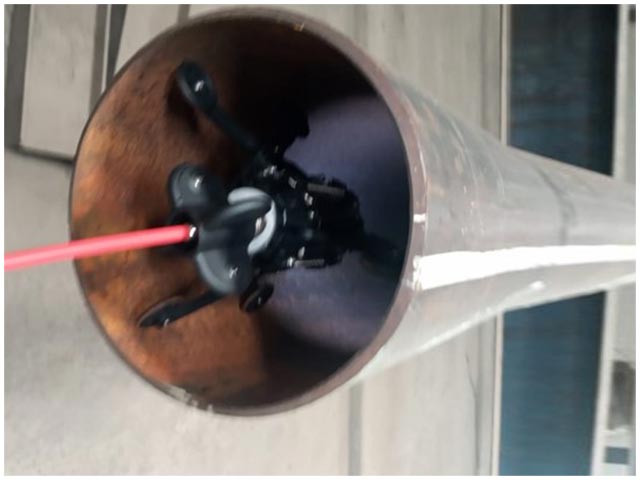

The RPIC2 camera was supplied to achieve the purpose of visual inspection from inside the pipe to aid in quality checking & monitoring as a part of the QC process. They use RPIC2 pipe inspection camera for feasible weld inspection to see visual welding defects inside the pipes in 10 to 20 meters length range. The RPIC2 Video Pipe Inspection Camera is based on a 23mm camera head (diameters), in order to inspect 300mm dia steel pipe a customized universal roller skid was provided as part of kit to centralise the camera head while inspection.

The standard centralizer provides capability to inspect pipes of dia 40 to 150 mm.

The customized centralizer enhances the capability to be used for 70 to 300 mm dia pipes to meet the application requirement of M/S Jindal Pipes.

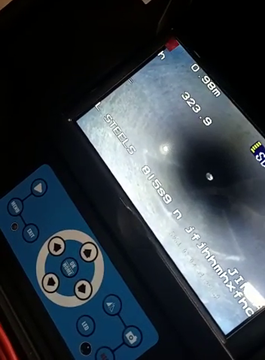

The output data is displayed on 7 inch HD color monitor with the capability to take snapshots along with the video for further analysis.

to take snapshots

The system encoder displays the length traveled to allow the QC inspector to know the location of inspection & defect if any, with further ability to add notes via annotators for future reference.

Jindal industry with its high focus on quality control, by way of uses of RPIC2 pipe inspection camera, will ensure even better-quality control for products manufactured for customer satisfaction.