| Physical |

|

| Weight: |

13.5 ounces (with batteries) |

| Size: |

Width (2.5 in/63.5 mm), Height (6.5 in/165 mm), Depth (1.24 in/31.5 mm) |

| Operating Temperature: |

14˚ to 140˚F (-10˚C to 60˚C) |

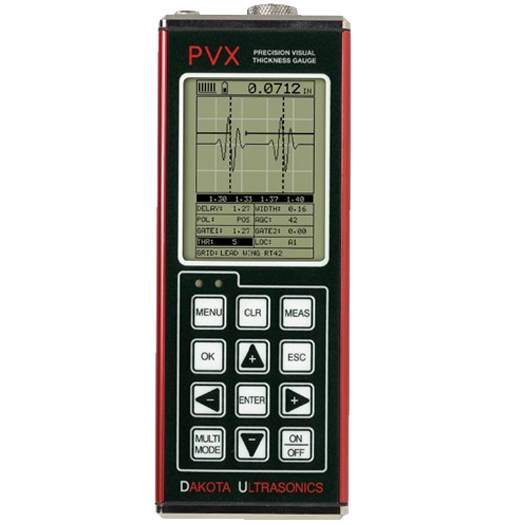

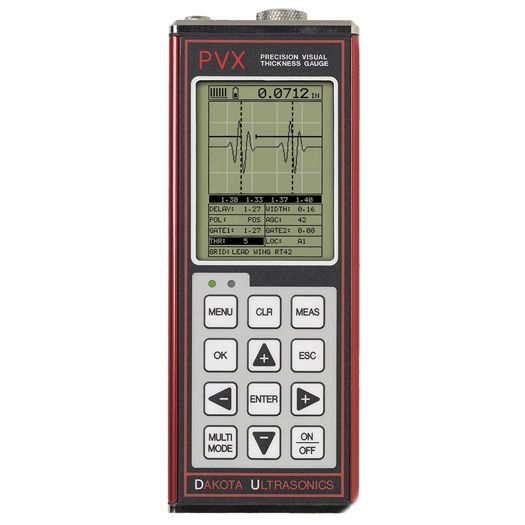

| Keyboard: |

Membrane switch pad with twelve tactile keys. |

| Case: |

Extruded aluminum body with nickel-plated aluminum end caps (gasket sealed). |

| Data Output: |

Bi-directional RS232 serial port; Windows® PC interface software. |

| Display: |

1/8 inch VGA grayscale display (240 x 160 pixels); Viewable area 2.4 x 1.8 inch (62 x 45.7mm); EL backlit (on/off/auto/invert) |

| Ultrasonic Specifications |

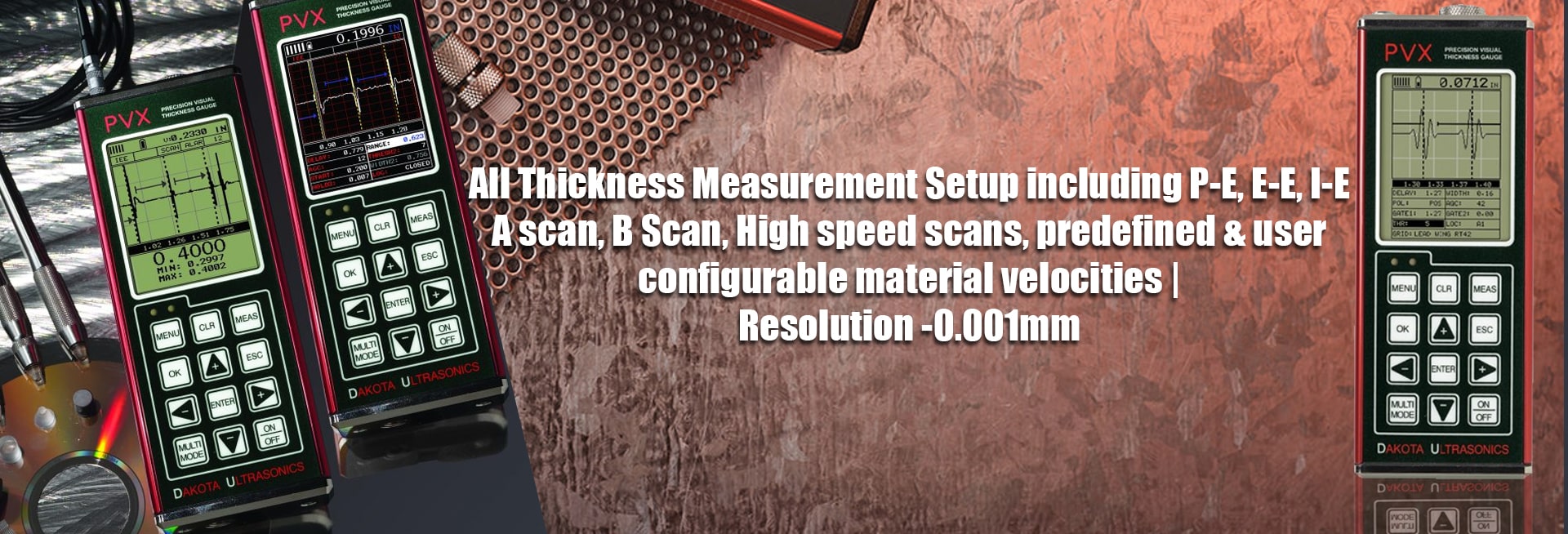

| Measurement Modes: |

Pulse-Echo (Precision—General purpose). Interface-Echo (Precision—Thick materials). Echo-Echo (Precision—Thin materials & thru-paint). |

| Pulser: |

Square wave pulser with adjustable pulse width (spike, thin, wide). |

| Receiver: |

Manual or AGC gain control with 40dB range, depending on mode selected. |

| Timing: |

40 MHz with ultra low power 8 bit digitizer. |

| Power Source |

| Three 1.5V alkaline or 1.2V NiCad AA cells. |

| Typically operates for 150 hours on alkaline and 100 hours on NiCad (charger not included). |

| Auto power off if idle 5 minutes. |

| Battery status icon. |

| Measuring |

| Range: |

| Interface-Echo Mode: |

Steel .050–1.0 inch (1.27–25.4mm); Plastics from .005 inch (.127mm) |

| Echo-Echo Mode: |

Steel .006–.500 inch (.152–12.7mm) |

| Pulse-Echo Contact: |

Steel .040–10.0 inch (1–254mm); Plastics from .010" (.254mm) |

| Echo-Echo Contact: |

Steel thru-paint .100–3.0 inches (2.54–76.2mm) |

| Resolution (selectable): |

+/- .001 inch (0.01 mm), +/- .0001 inch (0.001 mm) |

| Velocity Range: |

.0492 to .3936 inches/μs 1250 to 9999 meters/sec

One and Two Point calibration option, or selection of basic material types. |

| Units: |

English & Metric |

| Display |

| Display Views: |

| A-Scan |

Rectified +/- (half wave view) RF (full waveform view). |

| B-Scan |

Time based cross section view. Display speed of 15 secs per screen. |

| Large Digits |

Standard thickness view. Digit Height: 0.400 inch (10mm). |

| Scan Bar Thickness |

6 readings per second; Viewable in B-Scan and Large Digit views. |

| Repeatability Bar Graph |

Bar graph indicates stability of reading. |

| Data Logger (Internal) |

| 12,000 readings and waveforms (alpha numeric storage). |

| OBSTRUCT to indicate inaccessible locations. |

| Memory: |

16 megabit non-volatile ram. |

| Transducer |

| Transducer Types: |

Single Element (1 to 20 MHz). |

| |

Locking quick disconnect "00" LEMO connector. |

| |

Standard 4 foot cable. |

| |

Custom transducers and cable lengths available. |

| Features: |

| Setups: |

16 factory and 48 custom user-defined setups. |

| Gates: |

Single gate in contact mode; Single gate with holdoff in interface-echo, echo-echo, and plastics mode; Adjustable threshold. |

| Multiple Measurement Modes: |

Selectable modes for use with a variety of applications. |

| Alarm Mode: |

Set Hi and Lo tolerances with audible beeper and visual LEDs. |

| Fast-Scan Mode: |

Takes 32 readings per second and displays the minimum reading found when the transducer is removed. Display continuously updates while scanning. |

| Certification: |

| Factory calibration traceable to national standards. |

Adjustable square wave pulser provides the flexibility necessary for both high resolution and penetration requirements.

Adjustable square wave pulser provides the flexibility necessary for both high resolution and penetration requirements.