| General |

Receiver |

|

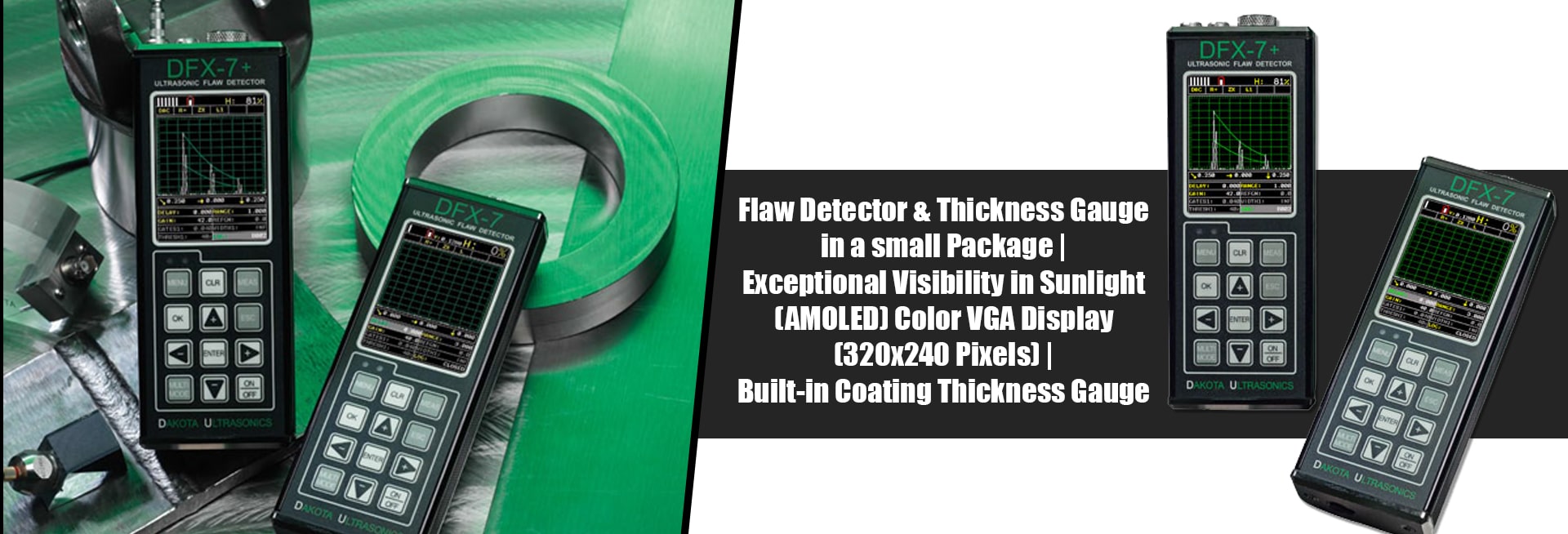

| Size: 2.5W x 6.5H x 1.24D in (63.5 x 165 x 1.5mm). |

Gain: 0 to 110dB with 0.2dB resolution. Manual

and AGC control. |

Echo-Echo Mode (E-E) - (Thru Paint & Coatings)

range 0.050 to 4.0 inches (1.27 to 102 millimeters). |

| Weight: 14 ounces (.397kgs), with batteries. |

Damping: 50, 75, 100, 300,

600, & 1500 ohms. |

Single Delay Line - 0.007 to 1.00 in (.178 to

25.4 mm). Single Contact - 0.040 in to 10 ft. (1

mm to 305 cm). Will vary based on coating. |

Case: Extruded aluminum body with nickel

plated aluminum end caps (gasket sealed). |

Frequency Bands: DFX-7 & 7+: Broadband 1.8 - |

Echo-Echo Verify (E-EV) - (Thru Paint & Coatings)

range 0.050 to 1.0 inches (1.27 to 25.4 millimeters). Will vary based on coating. |

Display: 1/4 VGA AMOLED color display (320 x240

pixels). Viewable area 1.7 x 2.27 in (43.2 x

57.6 mm). 16 color pallete, multiple color options,

and variable brightness. |

19 MHz (-3dB). DFX-7+: Three narrow bands at

2MHz, 5MHz, 10MHz. |

Coating Only Mode (CT) - (Coating Thickness)

range 0.0005 to 0.100 inches (0.0127 to 2.54

millimeters). Range will vary +/- depending on

the coating.

One and two point calibration option for material & coating, or selection of basic material types.

Auto probe zero, recognition and temperature

compensation.

High speed scan up to 50 readings per second.

Audible alarm with hi/lo limits.

Built-in differential mode for QC inspections.

Linear time dependent gain (TDG) with adjustable slope (dB per microsecond). |

| Screen Refresh Rate: 60Hz. |

Horizontal Linearity: +/- 0.4% FSW. |

Memory |

| Display Views: Flaw Detector: Full wave, +/- Recti7ed, or RF. Thickness Gauge: Digits, +/- Recti- |

Vertical Linearity: +/- 1% FSH. |

Log Formats: Grid (Alpha Numeric), or SequenMemory

tial (Auto Identi7er). |

| 7ed, RF, or B-Scan. |

Ampli4er Linearity: +/- 1 dB. |

Capacity: 4 Gb internal SD card. |

Resolution (selectable): +/- 0.001 in (0.01 mm )or

+/- 0.0001 in (0.001mm). |

Amplitude Measurement: 0 to 100% FSH,

with 1% resolution. |

Screen Capture: Bitmap graphic capture for

quick documentation (.tif ). |

| Timing: Precision TCXO timing with single shot |

Delay: 0 - 999in (25,375mm) at steel velocity. |

Custom Setups: 64 user con7gurations. |

| Resolution (selectable): +/- 0.001 in (0.01 mm)or +/- 0.0001 in (0.001mm). |

Flaw Detector Features |

Power Source |

| Timing: Precision TCXO timing with single shot 100 MHz 8 bit ultra low power digitizer. |

TRIG: Trigonometric display of beam path,

depth, surface distance, and curved surface correction.

Used with angle beam transducers. |

Battery: Three 1.5V alkaline, 1.2V AA Nicad cells,

1.2V AA NI-MH, or other other equivalent power source. |

Measurement Gates: Two independent gates

(Flaw), and three gates (thickness). Start & width

adjustable over full range. Amplitude 5-95%, 1%

steps. Positive or negative triggering for each

gate with audible and visual alarms. |

DAC: Up to 8 points may be entered and used to

digitally draw a DAC curve. Reference -2, -6 -10, (-6/-12), (-6/-14), (-2/-6/-10) dB. Amplitude

displayed in %DAC, dB, or %FSH. |

Battery life (continuous use): Alkaline (12

hrs), Nicad (5hrs), and NI-MH (12hrs), with default settings. |

| Operating Temperature: 14 to 140F (-10C to 60C). |

AWS: Automatic defect sizing in accordance

with AWS D1.1 structural welding code |

Line Power: USB-C to PC or power outlet. |

| Environmental: Meets IP65 requirements. |

AVG/DGS: Automatic defect sizing using probe

data. Stores up to 64 custom setups |

connections. |

| Calibration: |

TCG: Time corrected gain. 50 dB dynamic range,

20 dB per microsecond, up to 8 points for curve

de7nition. |

Output: Direct USB-C 1.1 PC connectivity. |

Automatic Calibration: Longitudinal (straight),

Calibration

or Shear (angle). |

Thickness Gauge Features |

Transducer Connectors: Two LEMO 00 |

Probe Types: Single Contact, Dual, Delay, and

Angle . |

Measurement Mode: Pulse-Echo (P-E) range

0.025 in to 100 ft. (0.63mm to 3048 cm). |

Certification |

Units: English (in), Metric (mm).

Velocity: 0.0100 to .6300 in/µs (256–16,000 m/s). |

Auto-Cal: Provides automatic calibration with two reference points. |

Thickness Gauge: Factory calibration traceable To LEMO 00 Certi4cation

to NIST & MIL-STD-45662A. |

Test Range: 0.007 in (.178mm) to 1200 in (30,480mm) maximum at steel velocity.

Continuously variable.

Zero Offset (Probe Zero): 0–999.999 µs.

Material Velocity Table: Contains longitudinal

and shear velocities for a variety of material

types. |

Detection Modes: Zero Crossing, Flank and Peak. |

Flaw Detector: EN12668-1 compliant. |

| Pulser |

Display Freeze: Hold current waveform on

screen. |

Warranty : 2 year limited |

Pulser Type: Two adjustable square wave pulsers

and receivers. |

Peak Memory: Captures peak signal amplitude. |

|

P.R.F.: 8 to 2000Hz in selectable steps (8, 16, 32,

66, 125, 250, 333, 1000, 2000Hz). |

Skip Bar: Displays skip legs in the waveform area. |

|

Pulser Voltage: 100-200 volt peak amplitude,

rise/fall time < 10ns into 50ohm. |

Measurement Modes (Dual & Single Element):Thickness Gauge Features Pulse-Echo Mode (P-E) - (Pit & Flaw Detection)

range 0.025 to 96 in (0.63mm to 244 cm). Single

Contact - 0.040 in to 100 ft. (1 mm to 3048 cm).

Pulse-Echo Coating Mode (PECT) - |

|

Pulse Width: 40 to 400 ns. Selectable step options 40, 80 & 400 ns

(labeled spike, thin & wide). |

(Material,

Coating, Pit & Flaw Detection): Material: 0.025 in

to 96 in (0.63mm to 244 cm). Coating: 0.001 to

0.100 inches (0.01 to 2.54 millimeters).

Pulse-Echo Temp Comp Mode (PETP) - (Pit &

Flaw Detection) Auto temperature compensation

-range 0.025 in to 96 in (0.63 mm to 244 cm). |

|

| |

|

|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)