- Underground Locating Equipment

- Buried Pipe and Cable Locators

- DXL4 Cable Avoidance Tool

- MXL4 Pipe & Cable Locator

- DXL3 Cable Avoidance Tool

- STLOC10 GPS Pathfinder Pipe & Cable Route Tracer

- STLOC10 Pathfinder Pipe & Cable Tracer

- Pathfinder PLDL Survey Grade RTK GNSS Mapping Pipe & Cable Route Tracer

- STLOC3 Buried Pipe Cable Route Locating Equipment

- STLOC5 Pathfinder Pipe & Cable Locator

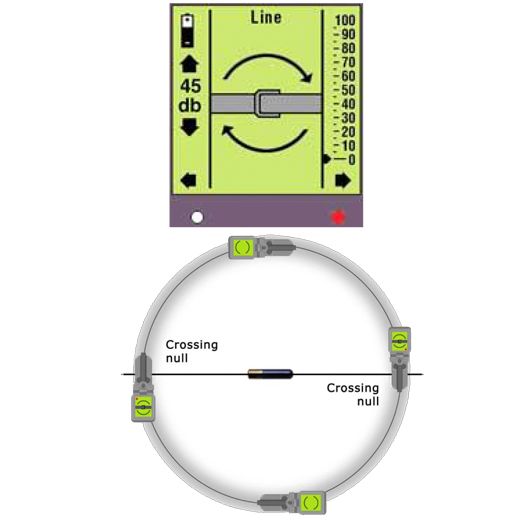

- Non Metallic PLB Telecom Duct Route Tracing System

- Cat 33 XD Cable Avoidance Tool

- Underground Utility Mapping GPR

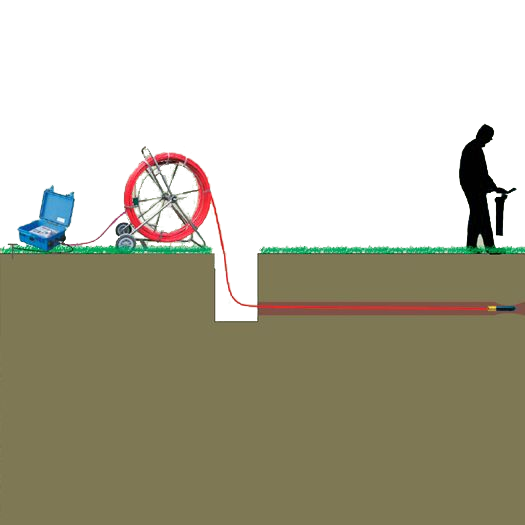

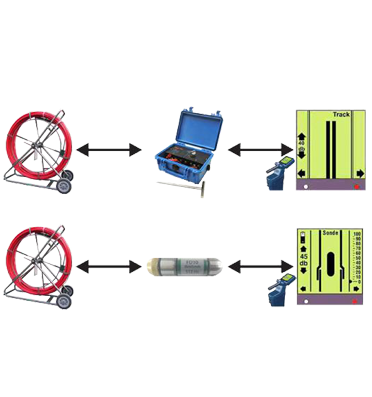

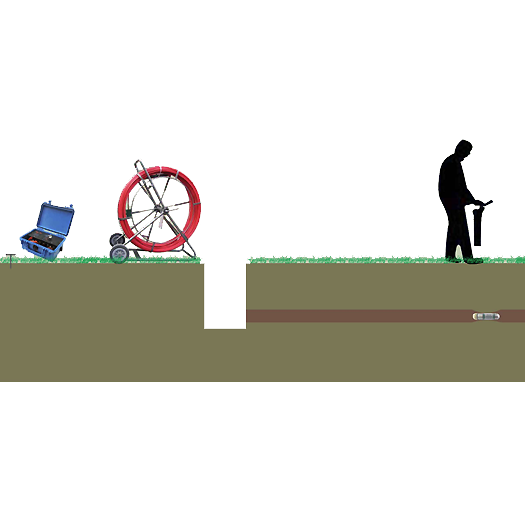

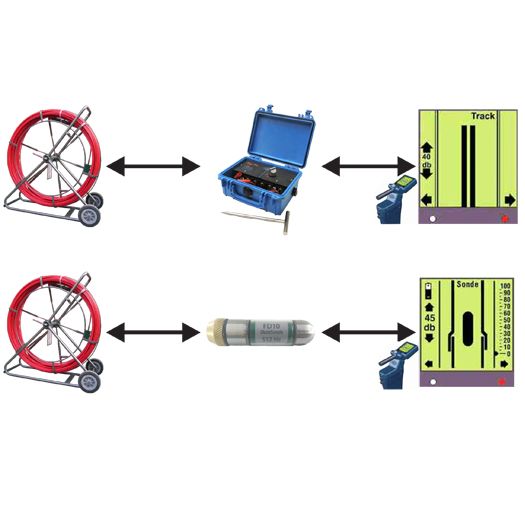

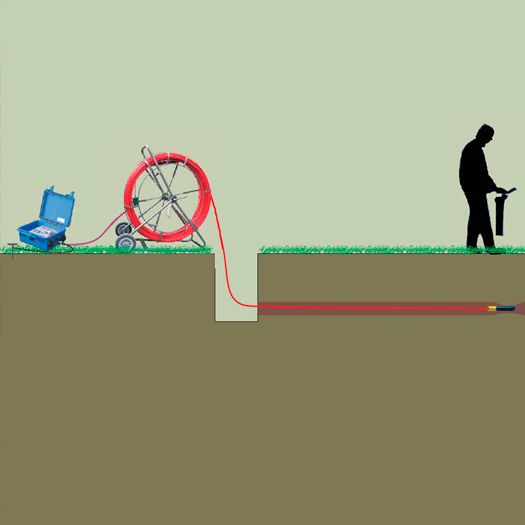

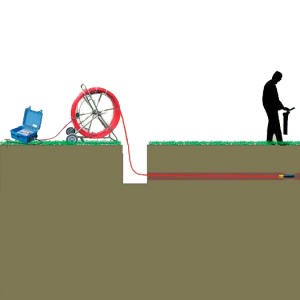

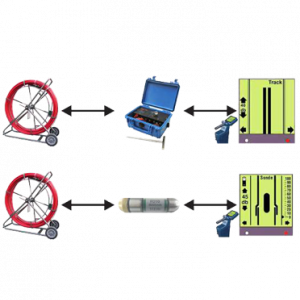

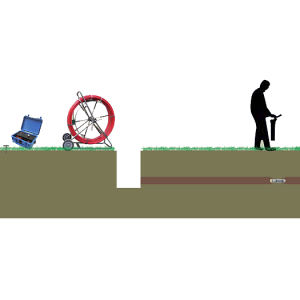

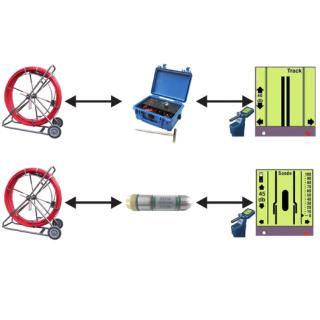

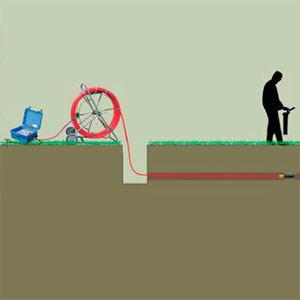

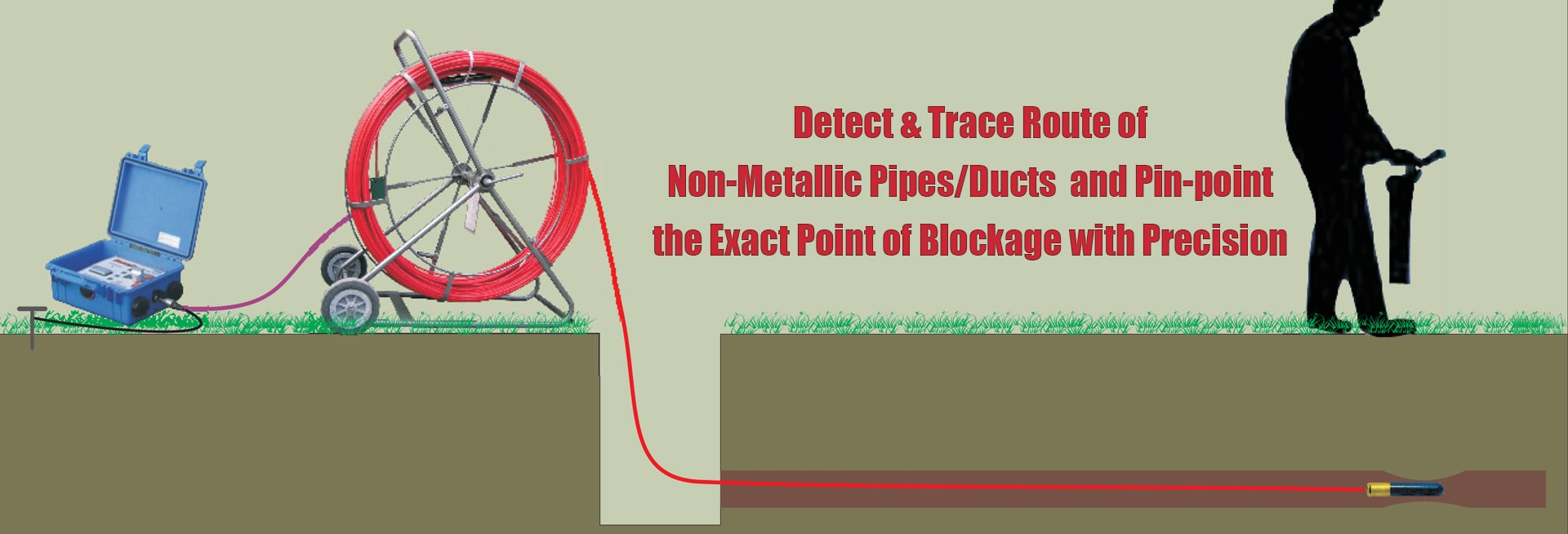

- Traceable Duct Rodder

- Electronic Markers and Locators

- Metal Detectors

- Manhole Cover Locator

- Ferromagnetic locator

- Buried Pipe and Cable Locators

- Cable Installation Equipment

- Water & Sewer line maintenance

- Pipe Inspection Camera System

- Water Leak Detection System

- DXmic Pro Digital Ground Microphone Water Leak Detector

- Lmic Water Leak Ground Microphone & Electronic Listening Stick

- PermaNet+ GPRS/4G Enabled Correlating Leak Noise Logger

- PermaNET SU LTE-M & NBIoT-enabled Correlating Leak Noise Logger

- PCorr+ Correlating Noise Logger

- Patroller 4 Wireless Transceiver

- Touch Pro High Performance Water Leak Noise Correlator

- Hydrophone 2 High Performance Plastic & Trunk Main Sensor

- PermaNET TM GPS Multi-Parameter Water Trunk Main Leak Detection

- ST20 Listening Stick

- Perija Plus Underground Water Leak Detector

- Perija Mini V-Pickup

- Perija Mini Vpro Water Leak Estimator

- Telecom Test Equipment

- OTDR

- Fiber Optic Splicing Machine

- Optical Loss Test

- Optical Power Meters

- Optical Light Source

- SLS 500 Optical Light Source

- KI 2800 Handheld Optical Light Source

- KI 9800 Pocket Fiber Optic Light Source

- AOS210 Optical Laser Source

- BOU350 Optical Laser Source

- 570XL-AS100-EMI Light Source

- 573XL 650nm LED Source

- 577XL AS100 850nm LED Source

- 577XL 850nm LED Source With M90

- 578 XL M90 1300nm LED Source

- 580 XL-EMI

- TDR Cable Fault Locator

- Fiber Optic Visual Fault Locators

- Network Analyzer

- Lan Testers

- Fiber Tools

- KI6680 Mini Fiber Inspection Probe

- KI 6610 Handheld Fiber Inspection Microscope

- Three Hole Optical Fiber Stripper TK-3

- Mid Span Slitter TK-11

- Mid Span Slitter TK-26

- Optical Fiber Cable Jacket Slitter TK-10

- Drop Fiber Cable Stripper TK-14

- Kevlar Cutter TK-25

- Single Fiber Protection Sleeve TK-15

- One-click Cleaner TK-20

- Cleaning Cassette TK-19

- Mechanical Splicer TK-30

- Fiber Cleavers

- Optical Fiber Identifier

- Fiber Optical Attenuator

- Tone & Probe Kit

- Fiber Optical Talk Set

- Rocoil Rail Current Transducer

- Bit Error Rate Tester

- Megger Cable Fault Test & Diagnostics

- Thermal Imaging Camera

- Handheld Thermal Imaging Camera

- STX 480/640 Handheld Auto & Manual Focus Thermal Imaging Camera

- S280 Handheld Thermal Imaging Camera

- S280 Pro Handheld Thermal Imaging Camera

- S300N-M Manual Focus Thermal Imaging Camera

- S320-M Manual Focus Thermal Imaging Camera

- S500-M Manual Focus Thermal Imaging Camera

- S600 Manual Focus Handheld Thermal Imaging Camera

- ST-120 Mobile Thermal Imaging Camera

- Fixed 24x7 Monitoring Thermal Imaging Camera

- Security Thermal Imaging Camera

- Handheld Thermal Imaging Camera

- Electrical Test & Measurement

- Personal Safety Voltage Detectors

- High Voltage Utility Testers

- Digital Multimeters

- SMM180 Trend Capture True RMS Datalogging Multimeter

- STANONE SMM606 20A True RMS Multimeter

- SMM909 Digital Multimeter

- SMM198 True RMS 20A Professional Multimeter

- 71D 40000 Counts True RMS Datalogging Multimeter

- 196 1700V DC True RMS Solar Multimeter

- 33A+ Palm Size Digital Multimeter

- 61D 10 A True RMS Multimeter

- 61A 10 A True RMS Multimeter

- 61E 10 A True RMS Multimeter

- 33 D+ Palm Size Digital Multimeter

- Clamp Meters

- STANONE SCM208 1000A True RMS Digital High Performance Clamp Meter

- STANONE SCM 204 AC/DC Digital Clamp Meter

- 1000 A AC Digital Clamp Meter 205A

- 2000 A AC/DC Digital Clamp Meter 221

- AC Digital Clamp Meter 201+

- STAN ONE SCM222 60A High Precision Clamp Meter

- High Voltage Clamp Ammeter 255A/B

- Power And Harmonics Clamp Meter 243

- True RMS Flex Clamp 281A/C/E

- Leakage Clamp Meters

- Insulation & Earth testers

- STAN ONE CET180 Clamp Earth Ground Tester

- STAN ONE CET 500 Digital Clamp Earth Resistance Tester

- SET500 Digital Earth Ground Tester

- 3/4 Wire Digital Earth Ground Tester 572

- STAN ONE SIT500 1KV Insulation Tester

- LV 1KV Insulation Tester 511

- 5 KV HV Insulation Tester 513

- 5 KV HV Insulation Tester 513B / 513C 5KV HV Digital Insulation Resistance Tester

- 12 KV HV Insulation Tester 516B

- Micro Ohm Meter 620A

- LV Handheld Insulation Tester Cum Multimeter 505A

- Temp/Light/Air/Sound Testers

- Oscilloscopes

- Current & Voltage Testers

- Infrared Thermometers

- Construction Surveying Equipment

- Laser Distance Meters

- Laser Level

- Digilevel 60 Inclinometer

- Digilevel Compact Inclinometer

- Revolution 310S Rotary Laser

- 5 Beam Laser Pointer

- Altimeter Ziplevel Leveling Measurement Instrument

- Auto Cross Laser ACL 2CRX Automatically Leveled Crossline Laser

- Crossliner ACL2RX Automatically Leveled Crossline Laser

- Evolution Cross Laser 8PRX Automatically Leveled 8 Beam Laser

- Auto Line Laser 3D Plus

- Concrete NDT Testing Equipment

- Ground Penetrating Radar Equipment

- Geotechnical & Structural Monitoring

- Pavement Testing Equipment

- Material Inspection Gauges

- Portable Hardness Testers

- Material & Coating Thickness

- ZX-1 Ultrasonic Thickness Gauge

- ZX3 Ultrasonic Thickness Gauge

- ZX5-Data Logging Ultrasonic Thickness Gauge

- ZX-6 Multi Echo Material Thickness Gauge

- CMX : Material Coating & Thickness Gauge

- Digital Ultrasonic Material Thickness Gauge - 160

- MX2-DL Ultrasonic Thickness Gauge

- PZX-7 Precision Thickness Gauge

- PMX2-DL Ultrasonic Precision Thickness Gauge

- MFD 500 Ultrasonic Flaw Detector

- ST310 Hardness Tester

- Bolt Tension Monitors

- Video Borescopes

- X750 Articulated Industrial Videoscope

- X2000 High Performance 4-Way Articulated HD Video Borescope

- STD500 2-Way Articulating Borescope

- SVTS850 Rotating Dual View Borescope

- STAN ONE SVBS450 Long Length Video Borescope Inspection Camera

- STAN ONE SVBS300 Video Borescope Inspection Camera

- ST WVBS

- 7" (Inch) High Resolution TFT Display Industrial Borescope MEGA-7

- STVB27R1M 2.7†LCD Video Recording Borescope

- Ultrasonic Flaw Detectors

- Coating thickness gauge

- Pipe Inspection Camera

- Catalogues

- Experience

- Video & training

- About Us

- Career

- Contact