Application requirement:

To scan & evaluate the pavement layer thickness & ensure the pavement is constructed as per the issued parameters.

APCO requires checking the pavement layer thickness (Includes bituminous layer, WMV & GSV) & to ensure the pavement is constructed as per the given specification & follows all the necessary guidelines.

Solution:

APCO uses C-thrue GPR for scanning Pavement layer thickness being constructed for Delhi-Vadodara Expressway, a project of NHAI ( National Highway Authority of India).

C-thrue is a high frequency 2 GHZ Dual Polarized Ground Penetrating Radar (GPR) for accurate scanning and real time analysis of Pavement layers. It assists EPC Contractors, Road Construction Companies & Public works departments to check & ensure that road construction is being constructed as per laid down design parameters. APCO uses C-thrue GPR for pavement layer scanning & evaluating the thickness of each layer.

Pavement Layers Design parameter is defined as:

Bituminous Layer - Total Thickness - 250 mm (100+80+70)

WMV - Total Thickness - 150 mm

GSV - Total Thickness - 200 mm

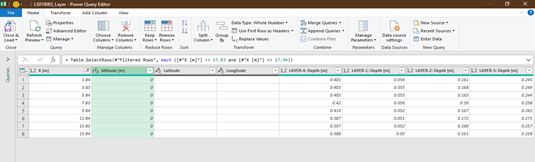

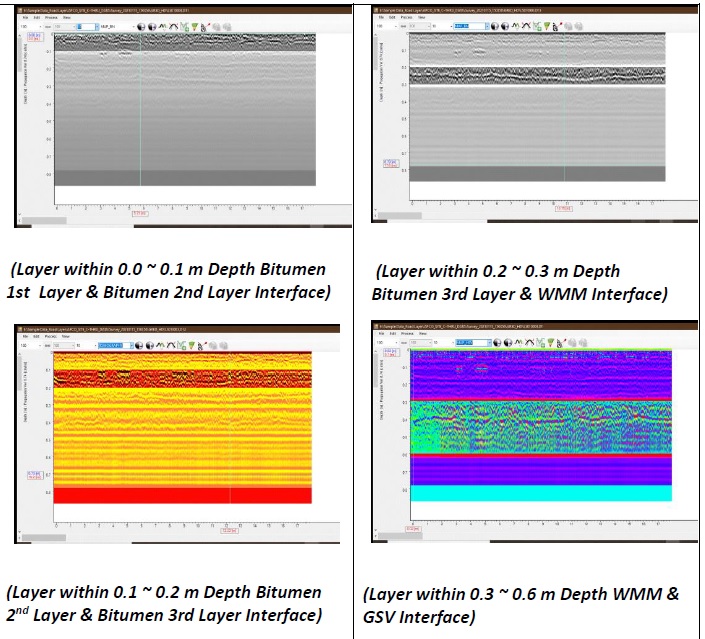

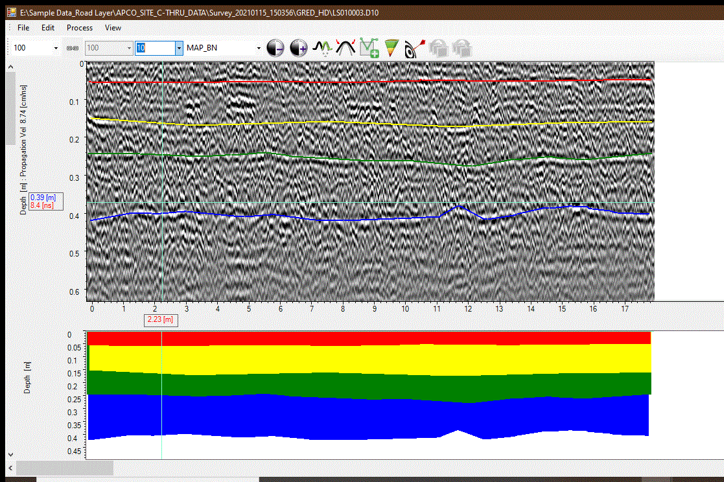

Step 2 (a)- Post processing of data using semi-automatic to automatic GRED 3D Software

For pavement layer data analysis, use of post processing software is necessary for interpretation of clear layer by layer depth. GRED 3D HD software allows semi-automatic to automatic post processing of pavement layer data requiring minimal human intervention allowing long lengths of kms to be post processed quickly.

In Step II, for clear representation of each layer, Output data were interpreted by post-processing GRED 3D HD software:

Step 2 (b) : Calibration of Bituminous Layer

They use a sample core & measure the thickness manually to calibrate data based on bituminous design layers thickness 250mm (80+100+70).

Pavement layer data was exported into excel for further access.