Application requirement:

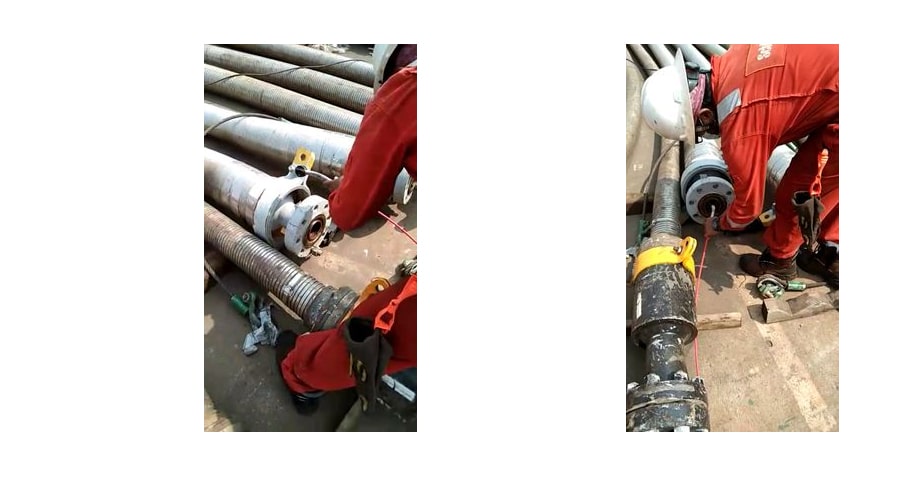

Visual inspection of high pressure semi-flexible corrugated steel pipes used for oil & gas industries.

Schlumberger requires visual inspection of corrugated steel pipes to detect internal damages as well as presence of foreign material within the pipes.

Solution:

RPIC2 pipe inspection camera is used for the visual inspection of high pressure semi-flexible corrugated steel pipes to detect the presence of foreign material as well as internal damages within the pipes.

Due to non-regular operation & storage in open yard, foreign material intrusion happens within high-pressure pipes causes the damage of connected plant & machinery, and creates risk for safety personnel. The RPIC2 pipe inspection camera was selected for the operation which is capable to provide high-resolution photos & videos for visual inspection of any damage to the internal surface of pipe & help in detecting the presence of foreign material.

RPIC2 Pipe Inspection camera system is a ruggedized, professional video inspection camera equipped with a 7” LCD monitor with DVR and 20m rotatable cable reel.

The RPIC2 Video Pipe Inspection camera is based on fiberglass semi-flexible rod with diameter 6.8 mm & with camera head 23 mm (diameter), in order to inspect high pressure corrugated steel pipe with internal diameter approx. 68 mm, a standard 46 mm skid (a part of kit) was used to centralise the camera head & slip over the corrugation.

The high-resolution output data is displayed on 7 inch HD color monitor with capability to take some snapshots along with the video for further analysis.

With a high focus on quality control & safety, Schlumberger by way of using an RPIC2 pipe inspection camera will ensure even better-quality control of products for customer satisfaction.